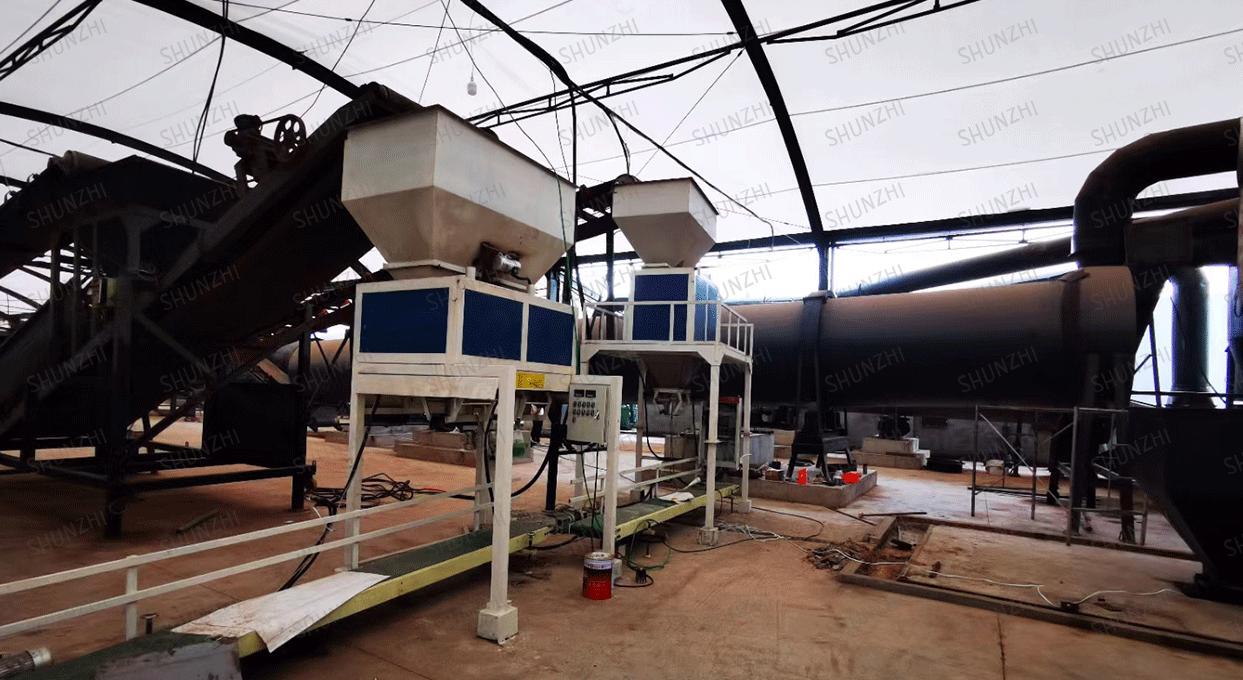

Spain Compound Fertilizer Granulation Production Line

Spain Compound Fertilizer Granulation Production Line

Common raw materials of compound fertilizer extrusion granulation production line:

1. Fertilizers: potassium sulfate, ammonium bicarbonate, potassium chloride, urea, Russian red potassium, NPK compound fertilizer, ammonium oxide, potassium nitrate, monoammonium phosphate, diammonium phosphate, ammonium sulfate, ammonium bicarbonate, magnetic fertilizer, etc.

2. Powder material: ferric oxalate, cyanuric acid melamine glue, antioxidant, bromochlorohydantoin, sodium chloride, sodium dichloroisocyanurate, sodium trichloroisocyanurate, cyanuric acid, bleaching powder concentrate , Zinc oxide, lead oxide, potassium carbonate, strontium carbonate, calcium oxide, calcium hydrogen phosphate, sodium metasilicate, sodium orthosilicate, cryolite, aluminum fluoride, brake powder, rubber and plastic additives, white carbon black, activated carbon , calcium aluminate, heavy calcium, common calcium, carnallite, phosphate rock powder, rare earth, metal powder, filler. Feed additives, arsenic, nicotinic acid, nicotinic acid glue, pharmaceutical intermediates, steelmaking auxiliaries, snow melting agents, environmentally friendly materials, etc.

Advantages of roller extrusion granulation production line equipment:

The non-drying compound fertilizer extrusion granulator production line saves energy, drying and cooling processes, has no environmental pollution, requires little investment, and is simple and easy to operate. The extrusion granulator and its related series of equipment can produce ammonium bicarbonate series fertilizers. Ammonium bicarbonate series compound fertilizer has stable properties of raw materials, and is not easy to heat up and volatilize, which is the primary problem to be solved by this process technology.

In the production process of the roller extrusion granulation production line, the friction coefficient between the material and the roller is small, the temperature rise is low, the energy consumption is low, and there is no pollution. At the same time, in order to meet the needs of customers, to achieve the purpose of “small investment, quick results and good economic benefits”. It is also equipped with a complete set of equipment for auxiliary inorganic fertilizer production lines such as pulverizers, mixers, bucket elevators, feeders, screening machines, and packaging scales according to user needs.