Henan Shunzhi Machinery Co., Ltd. was established in Gongyi, Henan in 1993. In 2006, a foreign trade branch was established in Zhengzhou, Henan Province, which is a professional manufacturer of organic fertilizer equipment.

With professional technology and excellent machine quality, Henan Shunzhi has reached cooperation with customers all over the world, and can provide each customer with drawing design, complete production line matching scheme and equipment installation training.

Since its establishment, Henan Shunzhi Machinery has been adhering to its original intention, designed many organic fertilizer production line solutions for customers, and reached cooperation with many customers!

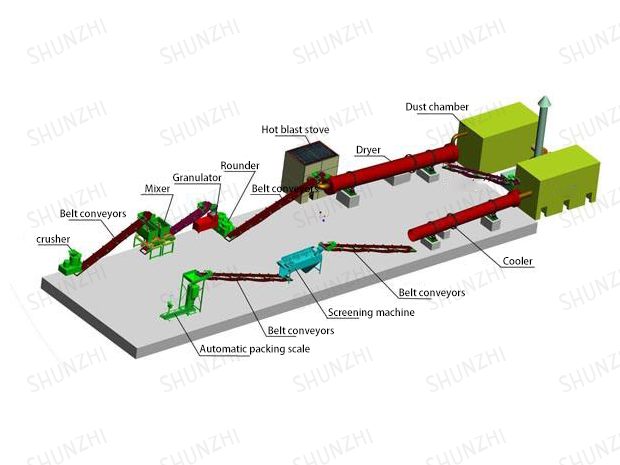

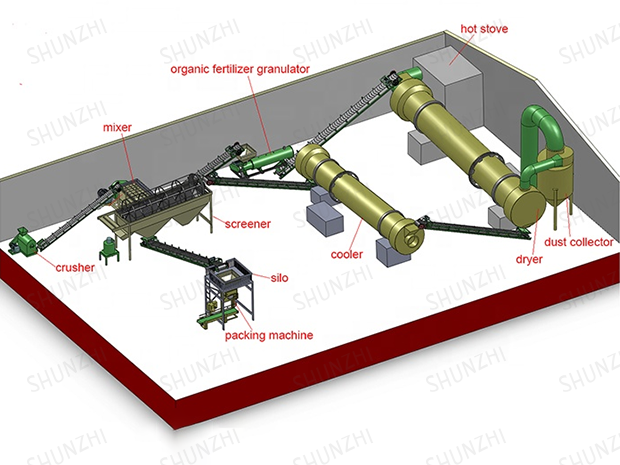

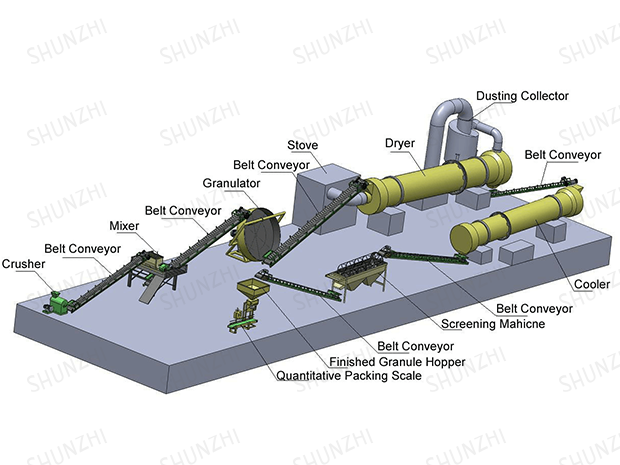

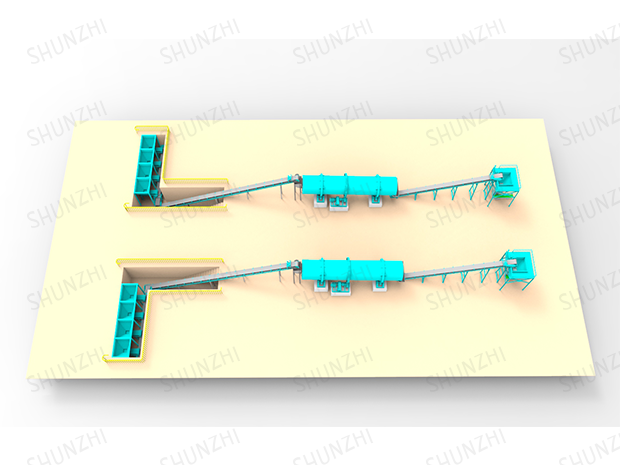

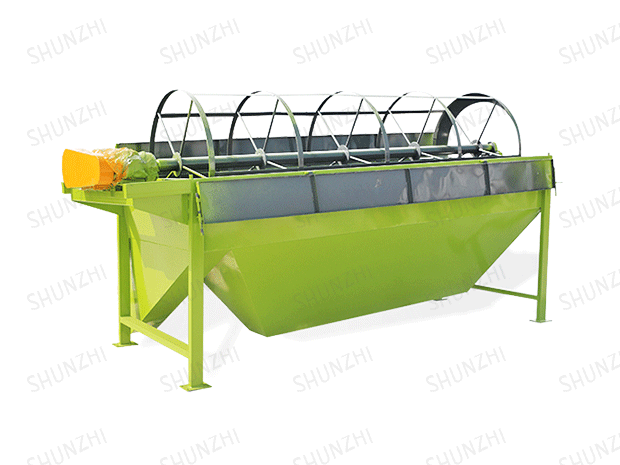

The pig manure organic fertilizer production line mainly crushes and mixes the composted pig manure, and then granulates. After granulation, the qualified products are screened by the trommel screen and then enter the dryer, and the dried materials enter the It is cooled by a cooler, and then processed by a coating machine to be packaged into bags.

Learn More >

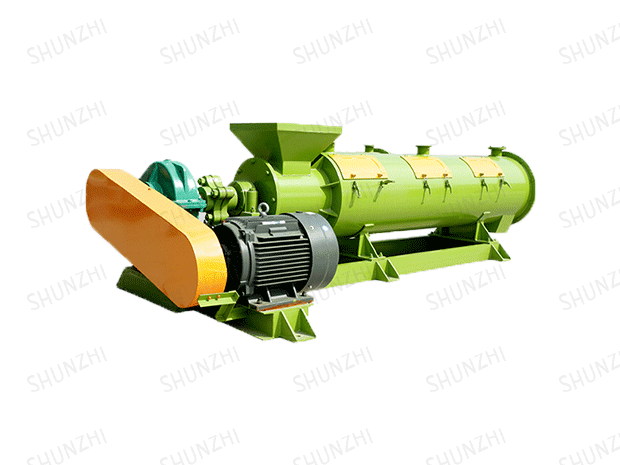

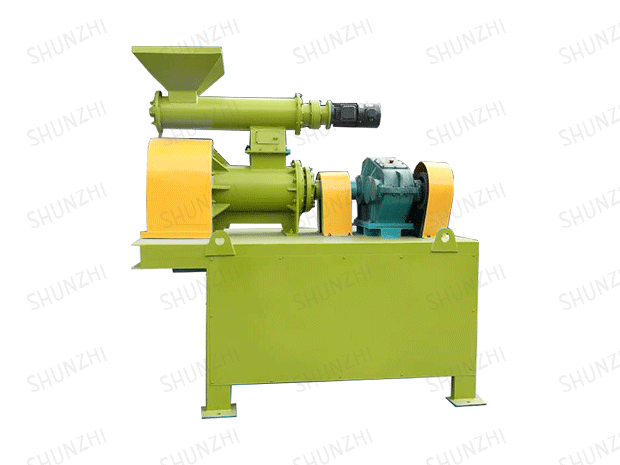

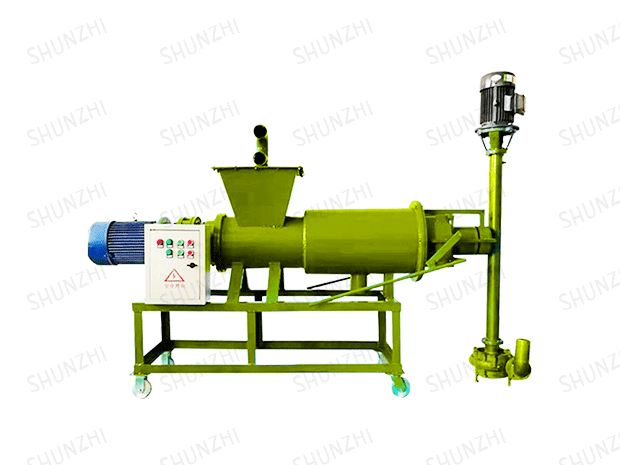

The non-drying compound fertilizer extrusion granulator production line saves energy, drying and cooling processes, has no environmental pollution, requires little investment, and is simple and easy to operate. The extrusion granulator and its related series of equipment can produce ammonium bicarbonate series fertilizers. Ammonium bicarbonate series compound fertilizer has stable properties of raw materials, and is not easy to heat up and volatilize, which is the primary problem to be solved by this process technology.

Learn More >

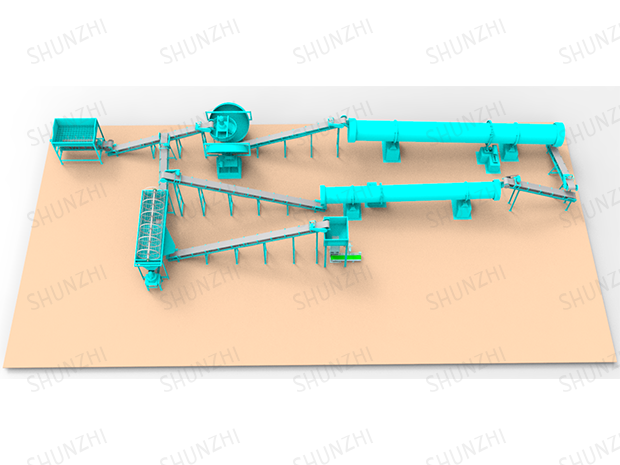

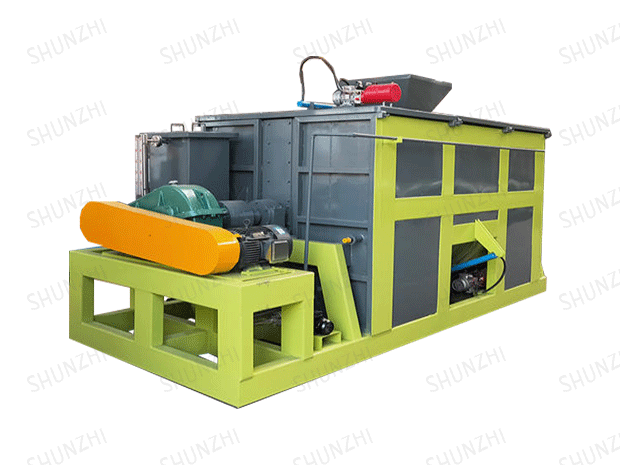

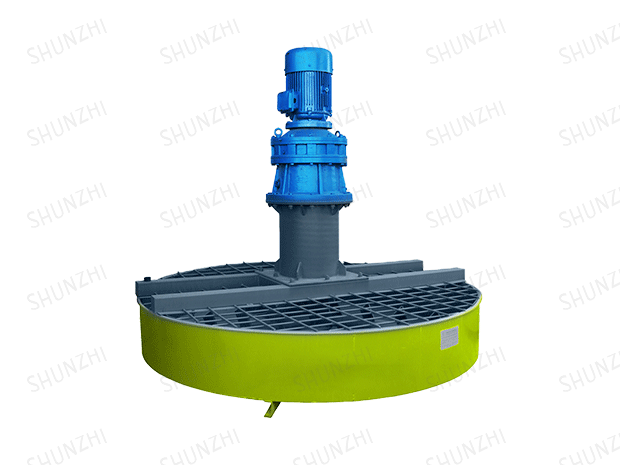

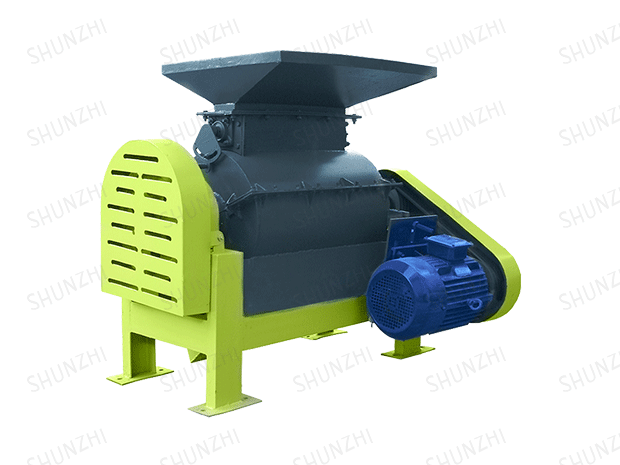

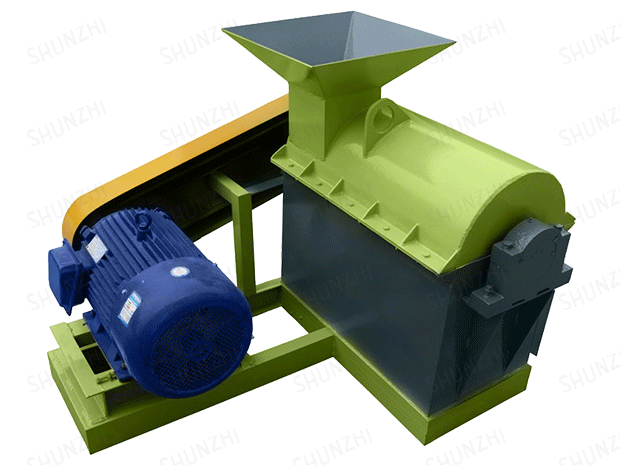

Semi-wet material pulverizer → horizontal mixer → new organic fertilizer granulator → dryer→cyclone dust collector → cooler → trommel screening machine → packing machine.

Learn More >

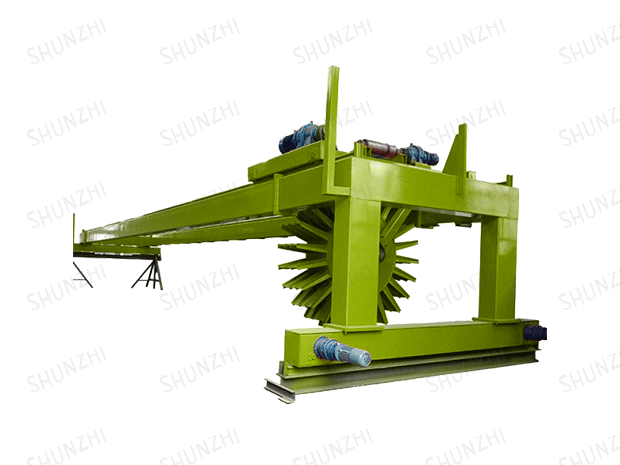

Strip-type composting process: The materials with suitable moisture adjustment are layered into strips according to height and width, and the strips are arranged in parallel on a flat compost field in the open air or indoors, and a professional turner is used to ride on the material. Continuous turning operations on the heap. The cross-sectional shape of the stockpile is triangular or trapezoidal: 1.5-2.5m wide, 0.8-1.4m high, and 50-150m long (depending on the shape and size of the composting site). The process features: the mechanical turning operation has strong mobility, and the use of strip stacks is conducive to the loss of water in the later stage of composting; low requirements for civil engineering, no need for supporting fermentation tanks, and can be composted outdoors, saving construction investment; composting site area needs to be relatively Larger; outdoor composting in northern regions has poor thermal insulation in winter, and the composting cycle needs to be extended or composting should be stopped seasonally; open-air composting is easily affected in the rainy season, and it is recommended to cover with a canopy if possible.

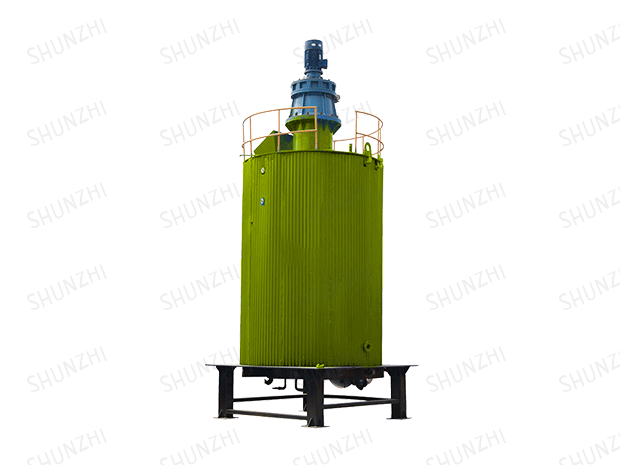

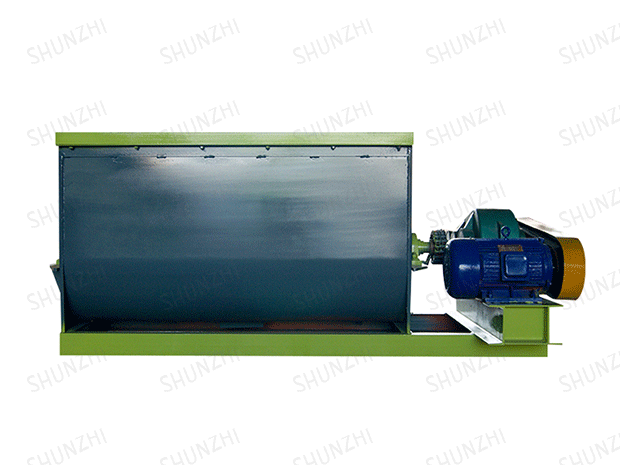

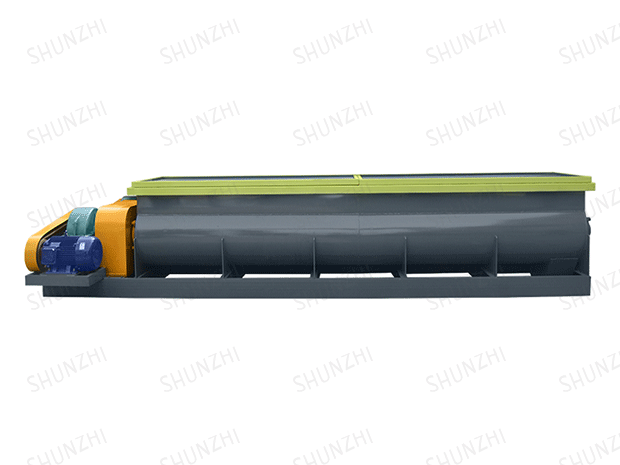

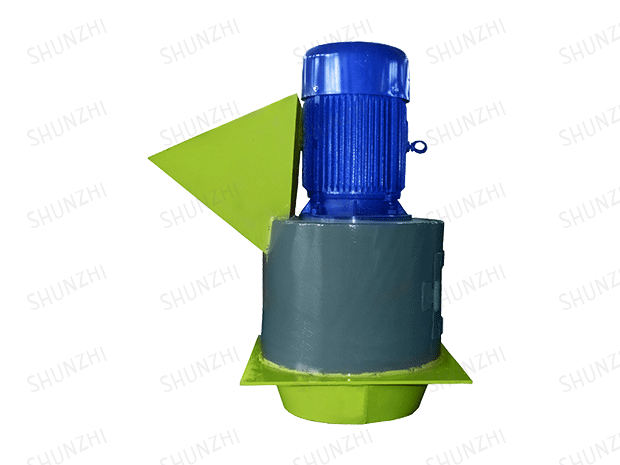

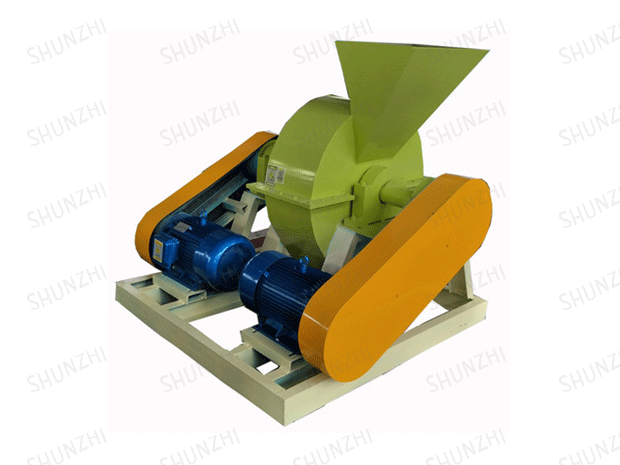

Learn More >The equipment produced by Henan Shunzhi Machinery includes: organic fertilizer pulverizer, mixer, screening machine, dryer, turning machine and other special equipment for organic fertilizer.

1-20

220/380

1-20

220/380

1-20

220/380

1-20

220/380

1-100

220/380

5-8

45+15

1-8

37-110

1-30

5.5-37

0.02-6

0.55-18.5

5-8

30-55

10-30

7.5-58

300-400

26-36

10-30

5.5-15

1-50

45

500-1500

85-156

5-10

5.5

2-12

7.5-15

2-15

7.5-22

20-45

7.5-11

1-8

7.5-11

3-20

22-55

1-8

11-15

4-8

18.5-30

4-10

11-15

1-8

22-75

1-16

5.5-37

1-18

5.5-45

1-18

5.5-45

1-50

2.2-11

10-20

4kw/5.5kw

The installation, repair, maintenance and collocation of organic fertilizer production line of organic fertilizer equipment!

Rotary drum compound fertilizer production line The equipment has less investment, quick effect and good economic benefits. The complete set of equipment has a compact process layout, scientific and reasonable, and advanced technology. Energy saving and consumption reduction, no discharge of three wastes, stable operation, reliable operation and convenient maintenance.

Common problem

According to customer requirements, we can design 10,000-500,000 tons of organic fertilizer production lines and workshop design, provide complete sets of organic fertilizer equipment, BB fertilizer complete sets, organic and inorganic fertilizer equipment, high, medium and low tower fertilizer equipment, drum steam compounding ( He) fertilizer equipment, urea-formaldehyde fertilizer equipment, amino acid fertilizer equipment, ammonia fertilizer equipment, fully melted shotcrete fertilizer equipment, urine-based shotcrete fertilizer equipment, extrusion fertilizer equipment and chicken manure and other high-humidity materials drying and fermentation equipment.

Common problem

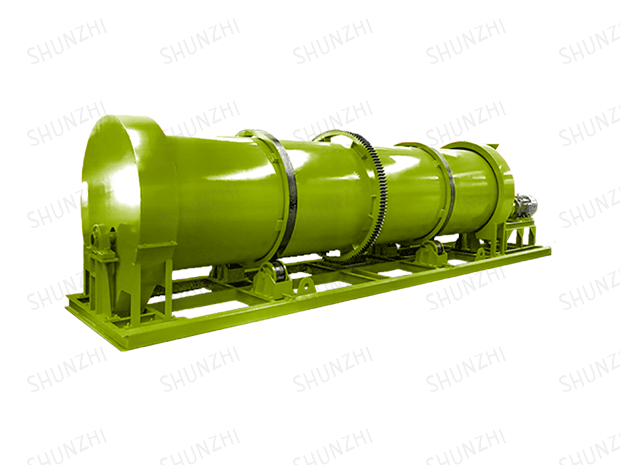

The rotary drum dryer is a part of the equipment of the bio-organic fertilizer production line, which has a great effect on the compliance of the organic fertilizer granulation and forming rate, and at the same time reduces the time for the finished organic fertilizer granules. Since the tumble dryer in the organic fertilizer production line is a large-scale drying equipment, it is inconvenient to move, and the investment is also a large amount. If it fails, it will affect the work efficiency, and it will cause economic losses to the manufacturer. In daily production, how to maintain the tumble dryer?

Common problem

More product-related knowledge, more latest news about Henan Shunzhi!

Overseas marketing outsourcing services for small and medium-sized enterprises, with its high-quality products, perfect management system and professional technical services, have successfully completed Yutong, Rebecca, Red Star, Haier Group, Luozhou, Weihua Group, etc. Thousands of well-known companies...