Slovakia Pig Manure Organic Fertilizer Production Line

Slovakia Pig Manure Organic Fertilizer Production Line

The pig manure organic fertilizer production line mainly crushes and mixes the composted pig manure, and then granulates. After granulation, the qualified products are screened by the trommel screen and then enter the dryer, and the dried materials enter the It is cooled by a cooler, and then processed by a coating machine to be packaged into bags.

The technological process of pig manure organic fertilizer:

1. Pig manure compost crushing: Various raw materials such as composted pig manure organic fertilizer, NPK inorganic fertilizer and other additives are crushed, proportioned and mixed in proportion. Based on years of experience, the equipment matching suggestions are as follows: using a vertical pulverizer to pulverize pig manure compost is not easy to stick to the wall and block, and the multi-layer turbulent chain hammer structure improves the pulverization performance.

2. Automatic batching and mixing equipment The continuous batching scale adopts computer automatic control, dynamically displays the formula situation, can store multiple formulas, and has high batching accuracy, which is convenient for production statistics and management. The use of automatic ingredients is the fundamental means to achieve strict formula ingredients, avoiding the error of manual ingredients. The material mixing and stirring adopts a double-shaft mixer, and its blade structure is more suitable for materials with strong adhesion, and the materials are not easy to adhere, and it has the function of conveying while stirring.

3. Pig manure organic fertilizer granulation (organic fertilizer granulator) The organic fertilizer granulator is suitable for direct granulation of pig manure organic fertilizer after fermentation. The raw material does not need to be dried before granulation. After the raw material is crushed, it can be directly batched to process spherical pig manure organic fertilizer granules. %, the ball formation rate is above 96%. The drying process is saved and the manufacturing cost is greatly reduced. The organic fertilizer granulator makes the fine powder material continuously realize the processes of mixing, granulation, spheroidization and densification in the machine, so as to achieve the purpose of granulation. The particle shape of pig manure organic fertilizer is spherical, the sphericity is ≥ 0.7, the particle size is generally between 0.3-3 mm, and the granulation rate is ≥ 90%. The lower, the higher the rotational speed and the smaller the particles, and vice versa. Scope of application: This machine is especially suitable for the granulation of light and fine powder materials. The finer the basic particles of the fine powder material, the higher the sphericity of the particles and the better the quality of the ball.

4. Screening and return system The pig manure organic fertilizer granules output from the granulating and forming system have different particle sizes and need to be screened and classified. The selected rotary screener requires small vibration, low noise, convenient screen replacement, and is equipped with a screen surface cleaning device. It is recommended to be equipped with an automatic feeding system to screen unqualified large and small particles, transport them out through a belt elevator, re-pulverize them and then send them to a granulator for continuous granulation, which helps to improve the continuous operation capacity of the production line.

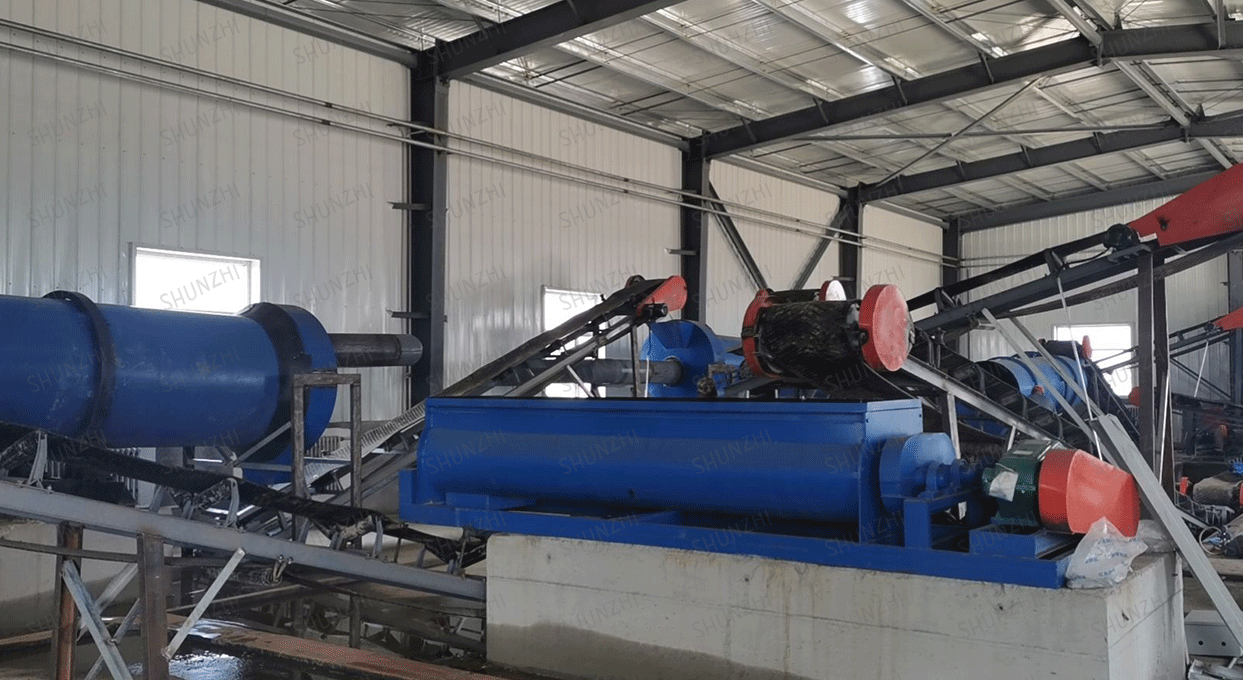

5. Particle drying system The function of the pig manure organic fertilizer dryer is to further remove the moisture from the screened pig manure organic fertilizer particles to meet the standard requirements of the water content of the organic fertilizer. Particle drying generally uses a tumble dryer, which improves particle formation while drying.

6. Particle cooling system (drum cooler) The dried pig manure organic fertilizer particles are conveyed to the cooler through the belt, and the rotary cooler is also a rotary cylinder with a lifting plate. The cold air in the body conducts heat exchange and is cooled to near normal temperature, which further improves the particle strength and reduces the moisture.

7. Envelope system After the pig manure organic fertilizer particles are cooled, they can be used as biological organic fertilizers, compound microbial fertilizers, and special organic fertilizers. The self-priming spray equipment can be used to spray attachments into the coating machine to improve the appearance or internal quality of the product.

8. Finished product packaging system Pig manure organic fertilizer granules are quantitatively weighed and packaged through an automatic packing scale. The automatic packing scale is controlled by a microcomputer, which can realize multi-range measurement. It has high weighing accuracy, automatic bag clamping, sewing, automatic tare weighting and detection functions. Its advantages are unmatched by manual packaging.