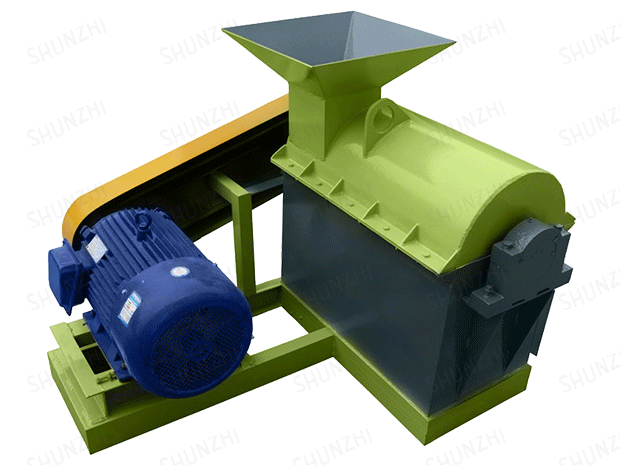

Brand: SHUNZHI

Model: SZSF-40/SZSF-60/SZSF-90/SZSF-120

Power: 22kw/30kw/37kw/75kw

Material: Animal waste, fermentation compost, etc.

Application: Bio organic fermentation fertilizer compost

The semi-wet material pulverizer is a professional semi-wet material pulverizer which is researched, improved and meticulously manufactured by the scientific research personnel of our factory who have collected advanced pulverizing technology at home and abroad, and have repeatedly researched, improved and carefully manufactured with many years of production experience. This machine solves the problem of crushing organic matter with high water content. The successful development of this machine has played a key role in shortening the process flow, reducing equipment investment and saving operating costs for bio-organic fertilizer and compost production.

The allowable moisture content of the bio-fermented organic fertilizer material reaches 25-50%, and the crushing particle size meets the granulation requirements. The crushing particle size can also be adjusted within the range according to user needs. It plays a role in grinding hard substances such as glass, ceramics, bricks, and gravel in the organic fertilizer of municipal solid waste. This machine is an ideal machine for fertilizer production and processing units.

1. Frame part: The normal operation of all machinery is inseparable from a solid frame. The frame of this machine is all welded with high-quality carbon steel plates and channel steel, and has passed strict product qualification certification and specific process requirements. In order to achieve the purpose of using this machine;

2. Rotor crushing part: The rotor of this machine is novel in structure and reasonable in design. It adopts two sets of rotor blades for crushing, and the crushing effect is twice that of other products. Continuous grinding to make the material meet the granulation requirements.

3. Crushing plate adjustment device: The fineness and output requirements of the crushed materials are determined by adjusting the distance between the crushing plate and the rotor blade during use.

4. Transmission connection part: The machine adopts flexible belt transmission. The pulley and belt are driven by the motor, and are directly transmitted to the main shaft, so that the main shaft rotates at a high speed to achieve the crushing effect.

| Model | Power(kw) | Capacity(t/h) | Crushing Granularity(mesh) | Inlet Size(mm) | Dimensions(mm) |

| SZSF-40 | 22 | 1-1.5 | 50 | 400*240 | 1200*1350*900 |

| SZSF-60 | 30 | 1.5-3 | 50 | 500*300 | 1300*1450*1300 |

| SZSF-90 | 37 | 3-5 | 50 | 550*410 | 1800*1850*1700 |

| SZSF-120 | 75 | 5-8 | 50 | 650*500 | 2100*2600*2130 |

Overseas marketing outsourcing services for small and medium-sized enterprises.