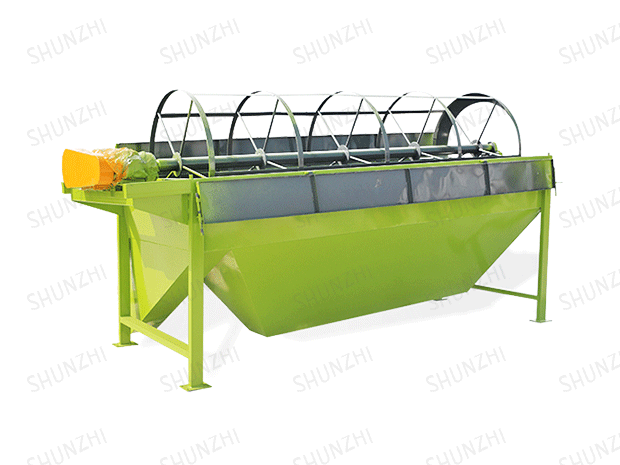

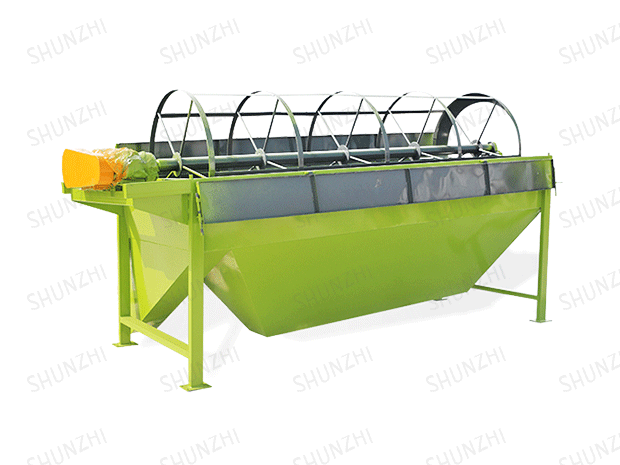

Brand: SHUNZHI

Model: SZGS-1020/SZGS-1030/SZGS-1240/SZGS-1540/SZGS-1560/SZGS-1870/SZGS-2080/

Power: 3kw/4kw/5.5kw/7.5kw/11kw

Use: Fertilizer Screening

The trommel screening machine, also known as the trommel screen, is widely used in the separation of bulk and granular raw materials such as compound fertilizer and organic fertilizer. After years of experience accumulation and technical improvement, Shuangxin Machinery has a compact structure and a greatly improved separation rate. The anti-blocking structure is added, the screening efficiency is higher, and the screen is made of manganese steel, which is more durable.

1. Frame part: The frame of this machine is welded with high-quality carbon steel plate and channel steel, and has passed strict product qualification certification and specific process requirements, and has achieved the purpose of this machine;

2. Transmission and screening part: This part adopts a combined screen, which is transmitted to the main shaft by the transmission wheel through the coupling, and the screen is installed and welded on the rolling cage of the main shaft. The material enters from the feeding end, is continuously rotated and graded in the rolling cage, and flows out evenly from the lower discharge port, which effectively separates the finished product from the returned material, thereby improving work efficiency;

3. Transmission connection part: The motor drives the pulley, the V-belt and the reducer to drive, so that the main shaft rotates, and the transmission reducer and the main working part are driven by the shaft-pin coupling, which is convenient for assembly and maintenance.

The motor of the trommel screening machine drives the reducer through the pulley, and the reducer drives the separation trommel screen drum through the coupling. The drum of the trommel screen is composed of several round steel rings, and the screen is fixed outside the ring for screening. The installation of the trommel drum is inclined to the horizontal plane. During work, the material enters the screen from the height of the trommel screen. During the rotation of the trommel screen drum, the fine materials are separated from top to bottom through the screen interval composed of round steel, the coarse materials are discharged from the end of the separation drum, and the fine materials are discharged from the lower end of the separation drum. During the separation process, through the relative movement between the cleaning mechanism and the screen body, the screen is continuously cleaned by the cleaning mechanism, so that the screen body is kept clean during the entire working process and is not blocked by the screen holes.

1. The screening efficiency is high because the equipment is equipped with a plate-type screen cleaning mechanism. During the screening process, no matter how sticky, wet and miscellaneous the material entering the separation screen is, the relative movement between the screen cleaner and the screen body will never block the screen. net, thereby improving the screening efficiency of the equipment.

2. Good working environment The entire screening mechanism is designed in a sealed dust cover, which completely eliminates the phenomenon of dust flying during the screening process, thereby improving the working environment.

3. Low equipment noise During the operation of the equipment, the noise generated by the material and the rotating screen is completely isolated by the sealed dust cover, so that the noise cannot be transmitted to the outside of the equipment, thereby reducing the noise of the equipment.

4. Long service life The equipment screen is composed of several circular flat steels with a specification of 16mm × 12mm, and its cross-sectional area is much larger than that of other separation equipment screens, so the service life is improved.

5. Maintenance is convenient. There are equipment observation windows on both sides of the sealed dust cover. During work, the staff can observe the operation of the equipment at any time. There are quick-opening doors for maintenance at the end of the sealing cover and the side of the screen cleaning mechanism. It is convenient and does not affect the normal operation of the device.

| Model | Power | Reducer | Drum Speed(r/min) | Capacity(t/h) |

| SZGS-1020 | 3 | ZQ250 | 21 | 1-2 |

| SZGS-1030 | 3 | ZQ250 | 21 | 2-3 |

| SZGS-1240 | 4 | ZQ250 | 18 | 3-5 |

| SZGS-1540 | 5.5 | ZQ350 | 16 | 5-8 |

| SZGS-1560 | 5.5 | ZQ350 | 16 | 6-10 |

| SZGS-1870 | 7.5 | ZQ400 | 12 | 10-15 |

| SZGS-2080 | 11 | ZQ400 | 12 | 10-20 |

Overseas marketing outsourcing services for small and medium-sized enterprises.