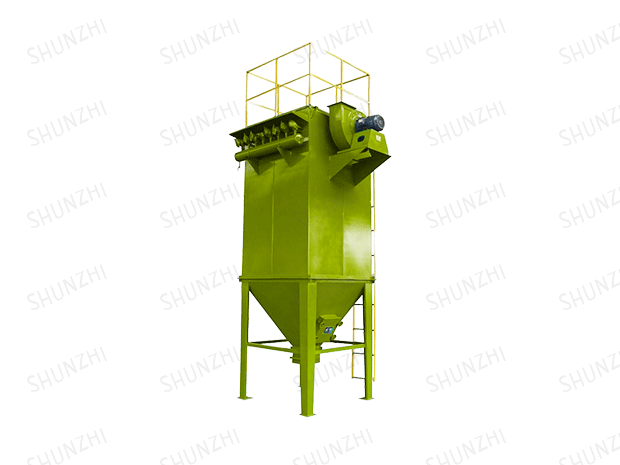

Brand: SHUNZHI

Model: HD8924/HD8932/HD8948/HD8956/HD8964/HD8972/HD8980/

Power: 3kw/5.5kw/7.5kw/11kw

Use: Dust Off

The type dust collector is specially designed for the top, bottom, belt conveying and local dust sources of cement plants. This machine is widely used in cement industry, and can also be used for dust removal in foundry industry, ceramic industry, glass industry, grinding wheel manufacturing, chemical products, machining and other industries. The bag-type dust removal unit is good for metal cutting, foundry sand, etc. with a large specific gravity and medium specific gravity dust, such as cement, ceramic raw material dust, pigment, bakelite powder, plastic powder, etc. Dust removal effect.

The bag filter is mainly composed of ash hopper, air inlet and exhaust duct, filter room (middle and lower box), clean room, filter bag and frame (bag cage bone), manual air inlet valve, pneumatic butterfly valve, pulse It is composed of ash cleaning mechanism, compressed air pipeline, platform escalator, electric control and so on.

The dust-laden flue gas passes through the filter material under the action of the induced draft fan, and the dust particles are filtered. Layers also have a certain filtering effect.

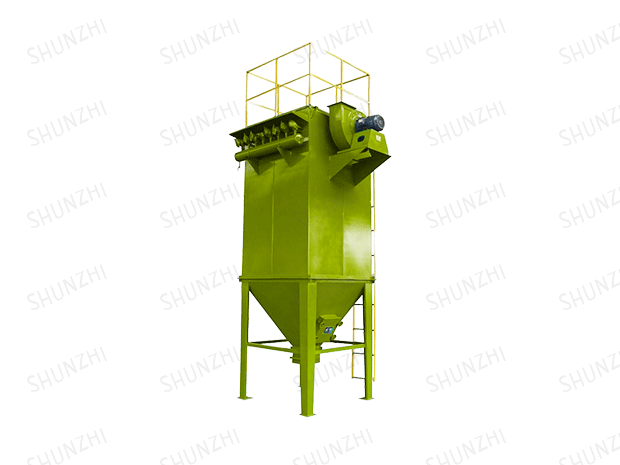

1. The equipment is a sub-chamber structure, with sub-chambers of different specifications, flexible and convenient combination, suitable for different sizes of boilers and layout of various sites. Adopting three-state cleaning, the cleaning effect is good, and the running resistance of the dust collector is low. Due to the long-term experiments and research on the injection system, the design methods of different filter bag combinations and different filter bag lengths have been mastered.

2. Various types of main pipes such as wedge-shaped and stepped entrances are used. Make the air distribution of each sub-chamber uniform. The ash hopper and air duct adopt advanced diversion device, which can reduce the resistance of the system and prolong the service life of the filter bag. . The selection of high-quality filter bag cage bones produced by special automatic equipment can ensure that the bag cage is flat, smooth, and has good dimensional accuracy, thereby prolonging the service life of the filter bag.

3. The flower plate produced by the multi-station automatic punching machine is flat and has good sealing performance with the filter bag. , Specially designed and manufactured sealed inspection door to prevent air leakage. Low leakage bypass poppet to prevent flue gas short circuits. Reliably sealed, insulated top cover.

4. Advanced automatic control equipment, with three control methods of differential pressure, timing and manual, realizes comprehensive system control of the off-line valve, pulse valve, ash discharge valve and bypass valve of the dust collector. The filter bags are available in different lengths, allowing the equipment to reduce the footprint.

| Model | Processing air volume (m³/h) | Dust collector resistance (Pa) | Filtration area (㎡) | Filtration Wind speed (m/min) | Dust removal efficiency (%) | Fan Power (KW) | Cleaning motor power (KW) | Type A weight (kg) |

| HD8924 (A、B、C) | 1000-1500 | 1200 | 10 | ≤2.5 | >99.9 | 3 | 0.25 | 680 |

| HD8932 (A、B、C) | 1500-2000 | 15 | 3 | 0.25 | 750 | |||

| HD8948 (A、B、C) | 2000-3000 | 20 | 5.5 | 0.25 | 893 | |||

| HD8956 (A、B、C) | 3000-3480 | 25 | 5.5 | 0.37 | 987 | |||

| HD8964 (A、B、C) | 3480-4200 | 29 | 7.5 | 0.37 | 1103 | |||

| HD8972 (A、B、C) | 4200-5200 | 35 | 7.5 | 0.37 | 1986 | |||

| HD8980 (A、B、C) | 5200-6000 | 40 | 11 | 0.55 | 1210 |

Overseas marketing outsourcing services for small and medium-sized enterprises.