Vietnam Chicken Manure Organic Fertilizer Production Line

Vietnam Chicken Manure Organic Fertilizer Production Line

Chicken manure is a good organic fertilizer, and its content of pure nitrogen, phosphorus (P2O5) and potassium (K2O) is about 1.63%, 1.54% and 0.85%. Chicken manure needs to be fully decomposed before application, and the parasites and their eggs in the chicken manure, as well as some infectious bacteria, are inactivated by the process of decomposing (retting).

The chicken manure organic fertilizer production line is a complete set of production equipment that uses fresh chicken manure as raw material and undergoes a series of processing to produce organic chicken manure fertilizer. The chicken manure organic fertilizer production line requires two steps to process commercial organic fertilizer: the pre-fermentation and treatment part and the deep-processing granulation part.

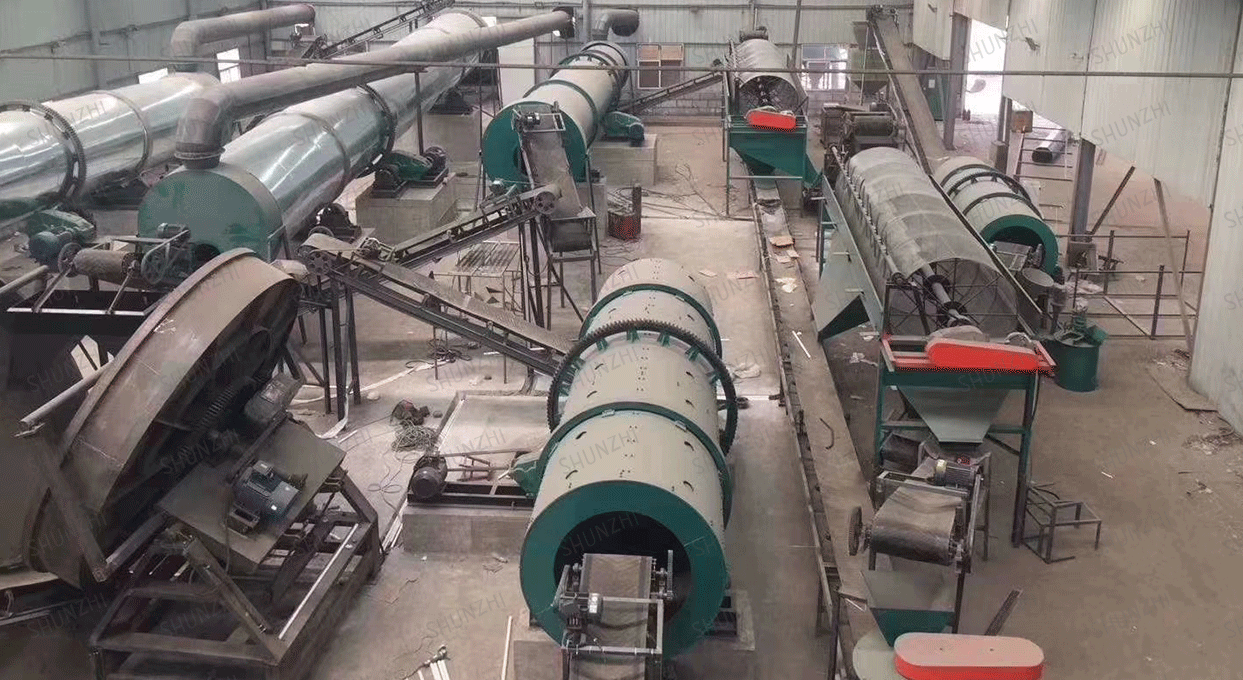

Main Equipment:

Bio-organic fertilizer equipment needs fermentation turner, organic fertilizer pulverizer, drum screening machine, horizontal mixer, disc granulator, rotary dryer, cooler, screening machine, coating machine, packaging machine, conveying machine machine and other equipment.

Chicken manure organic fertilizer production process:

1. Put the recovered livestock and poultry manure directly into the fermentation area. After primary fermentation, secondary aging and stacking, the odor of livestock and poultry manure is eliminated. Fermentation strains can be added at this stage to decompose the crude fiber, so that the particle size after crushing meets the particle size requirements of granulation production. 2. Pulverize the fermented materials that have completed the secondary aging and stacking process and enter the mixing and stirring system. Before mixing and stirring, according to the formula, add N, P, K and some other trace elements into the mixing and stirring system to start stirring. 3. The mixed material is transported into the granulation system, and the granulated material enters the cooling system after passing through the dryer. After the material is brought to room temperature, it starts to be sieved. The granules that meet the requirements enter the coating machine to wrap and coat and start packaging. The granules that meet the requirements are crushed by the pulverizer and returned to the granulation system to continue granulation. 4. The finished product is automatically weighed and packaged.

Trough aerobic fermentation: This is the most effective method for treating chicken manure at present, and it is also suitable for the commercial production of chicken manure organic fertilizer, which is conducive to standardized production. It uses biological characteristics combined with mechanization technology, uses natural microorganisms or inoculated microorganisms to decompose chicken manure and converts organic matter into organic matter, carbon dioxide and water. This method has a short fermentation time, generally about 15 days. The chicken manure can be fermented and decomposed, and It is easy to achieve factory-scale production, not affected by weather and seasons, and causes little pollution to the environment, which is conducive to the commercial production of chicken manure organic fertilizer. Depending on the equipment, the width of the fermentation tank is generally 3-20m, the depth is generally 0.8-1.5m, and the length is 50-100m, which can be designed according to the actual situation.