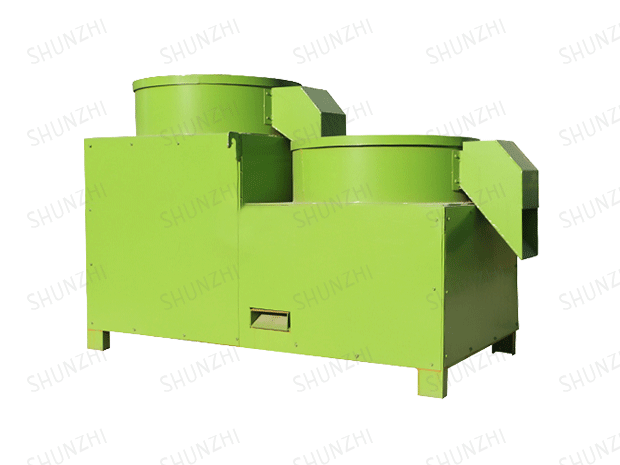

Brand: SHUNZHI

Model: SZPY-800/SZPY-1000/SZPY-1200/SZPY-1500

Power: 5.5kw/7.5kw/11kw

Use: Fertilizer Shaping

The organic fertilizer rounder is a rounding device configured on the basis of the organic fertilizer and compound fertilizer granulator. Ideal equipment for making spherical granules from organic fertilizers (biological).

The organic fertilizer round throwing machine is composed of two or three throwing cylinders arranged in sequence. The motor drives the throwing disc to rotate at a high speed, and drives the material in the cylinder to rotate at a high speed to form a high-speed rotating material flow. Rub against each other to quickly form spherical particles. The spherical particles initially formed in the shape-changing zone of the first zone automatically flow into the shape-changing zone of the second zone, and then flow out of the polishing machine after reaching the standard. Since the moisture of the particles is controlled at about 30-35%, the powder formed during the grinding process will instantly adhere to the surface of the particles, and the spheroidization rate is over 95%. After several rounds of rounding, the finished product is discharged from the discharge port, the particle size of the finished product is consistent, the sphere is round and smooth, and a small amount of fertilizer falls from the gap of the disk edge of the organic fertilizer rounding machine and flows out along the waste port.

The organic fertilizer granule rounder has high output and can be flexibly arranged in the process. It can be used together with the organic fertilizer granulator and the rounder to solve the complex process caused by the fact that a single granulator must be equipped with a single rounder. , large investment in equipment, inconsistent quality of finished products and other disadvantages.

| Model | Capacity(t/h) | Power(kw) | Pan Diameter(mm) | Overall Size(mm) |

| SZPY-800 | 1-2 | 5.5*2 | 800 | 2800*920*1290 |

| SZPY-1000 | 2-3 | 5.5*2 | 1000 | 3100*1020*1390 |

| SZPY-1200 | 3-5 | 7.5*2 | 1200 | 3400*1120*1490 |

| SZPY-1500 | 5-8 | 11*2 | 1500 | 3200*1550*1600 |

Overseas marketing outsourcing services for small and medium-sized enterprises.