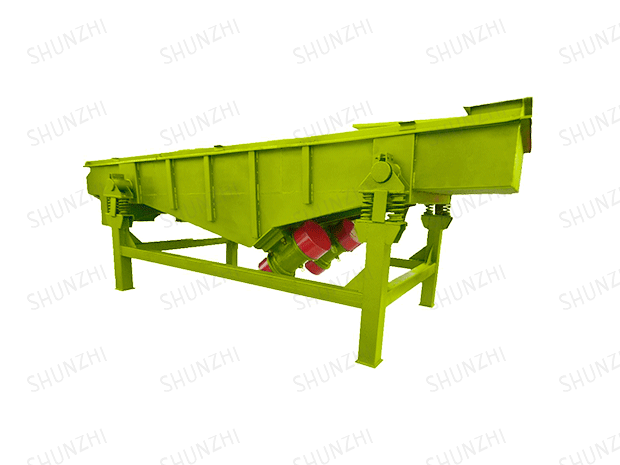

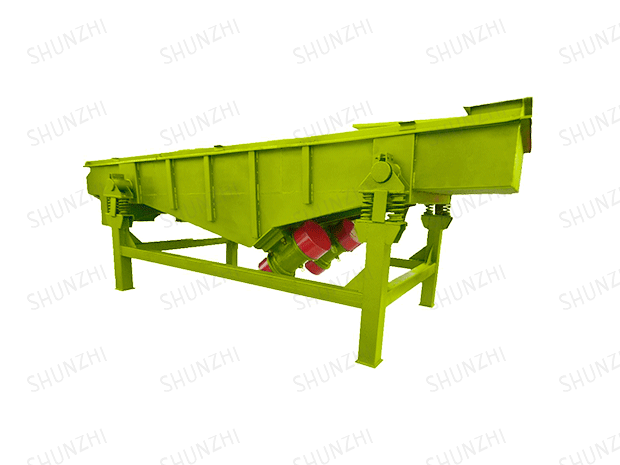

Brand: SHUNZHI

Model: SZF520/SZF525/SZF530/SZF535

Power: 2×(0.4~0.75)-2×(2.2~4)kw

Use: Screening

The linear vibrating screen is suitable for screening any dry material with 0.74-10mm, water content less than 7%, and non-viscous material. Mainly used for screening all kinds of powdery fertilizers.

When the two vibrating motors installed on the screen body in the longitudinal direction are operated relative to each other, the excitation force generated in the transverse direction cancels each other due to the relative operation of the motors, and the longitudinal excitation force is transmitted to the entire screen box through the vibration transmission body. The screen surface is vibrated, so that the material on the screen surface is subject to its exciting force and jumps on the screen surface in the direction of the discharged product. The material smaller than the screen hole passes through the screen hole and falls to the lower layer. The discharge port flows out. Due to the reasonable screening process, after the material is classified by the vibrating screen, several kinds of materials with different particle sizes can be obtained to complete the material classification operation.

1. Grading and screening various materials, the particles after screening are uniform in size and high in screening accuracy.

2. Generally, the design of a single unit varies from 1 to 5 layers, and the required number of layers can be selected according to different needs.

3. It has the advantages of convenient maintenance and relatively low maintenance probability.

4. The vibration source with adjustable angle is adopted, the screen is clean; the multi-layer design can be used, and there are many screens; it can be evacuated by negative pressure, and the environment is good.

5. It has a unique effect on the screening and classification of powdery and granular materials.

| Model | Nominal size (mm) | Material particle size (mm) | Incline angle (°) | Amplitude (mm) | Number of layers (s) | Power (kw) |

| SZF520 | 500×2000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(0.4~0.75) |

| SZF525 | 500×2500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(0.4~0.75) |

| SZF530 | 500×3000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(0.75~1.1) |

| SZF535 | 500×3500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(0.75~1.1) |

| SZF1020 | 1000×2000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(0.75~1.5) |

| SZF1025 | 1000×2500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(1.1~1.5) |

| SZF1030 | 1000×3000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(1.5~1.8) |

| SZF1035 | 1000×3500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(1.5~2.2) |

| SZF1040 | 1000×4000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(1.5~2.2) |

| SZF1225 | 1200×2500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(1.5~2.2) |

| SZF1230 | 1200×3000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(1.8~3) |

| SZF1235 | 1200×3500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(1.8~3) |

| SZF1530 | 1500×3000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(2.2~3) |

| SZF1535 | 1500×3500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(2.2~3) |

| SZF1540 | 1500×4000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(2.2~4) |

Overseas marketing outsourcing services for small and medium-sized enterprises.