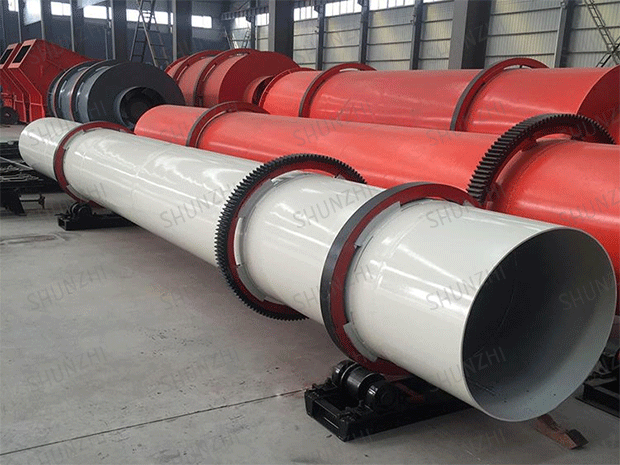

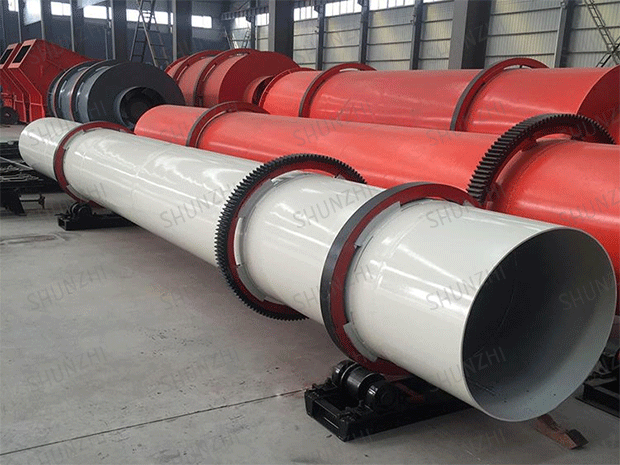

Brand: SHUNZHI

Model: SZHG-0808/SZHG-1010/SZHG-1212/SZHG-1515/SZHG-1616/

Power: 5.5kw/7.5kw/11kw/15kw/22kw/37kw/45kw

Use: Drying Manure

The pig manure dryer can make fresh pig manure with a moisture content of about 65, or other slag, through the process of feeding, high temperature drying, dust removal, cooling, etc., into an odorless granular product with a moisture content of less than 13%. It can be used as the main raw material of organic fertilizer or feed. The pig manure dryer has large operation flexibility and low drying cost. Strong adaptability and high reliability. The processing capacity is large, the fuel consumption is low, the overload resistance is strong, the cylinder runs smoothly, and the material can be quickly dried with high-temperature hot air. The design takes the production allowance into consideration, and even if the output increases slightly, there is no need to replace the equipment. The equipment adopts a self-aligning tug structure, and the tug and the rolling ring cooperate well, which greatly reduces the wear and power consumption. The specially designed retaining wheel structure greatly reduces the horizontal thrust caused by the tilting work of the equipment.

The dry wet material is sent to the hopper by the belt conveyor or the bucket elevator, and then enters the feeding end through the feeding pipeline through the feeding machine of the hopper. The inclination of the feeding pipeline should be greater than the natural inclination of the material, so that the material can flow into the dryer smoothly. The dryer cylinder is a rotating cylinder slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the low end, and is in countercurrent contact with the material, and some heat carrier and material flow into the cylinder together. With the rotation of the cylinder, the material runs to the bottom end by gravity. During the forward movement of the wet material in the cylinder, the heat is directly or indirectly supplied by the heat carrier, so that the wet material is dried, and then sent out through a belt conveyor or a screw conveyor at the discharge end. A copy board is installed on the inner wall of the cylinder, and its function is to copy and sprinkle the material, so as to increase the contact surface between the material and the air flow, so as to improve the drying rate and promote the advancement of the material. Heating medium is generally divided into hot air, flue gas and so on. After the heat carrier passes through the dryer, a cyclone dust collector is generally required to capture the materials in the gas. If it is necessary to further reduce the dust content of the exhaust gas, it should also be discharged after passing through a bag filter or a wet filter.

1. Bracket part: The bracket part includes a front bracket and a rear bracket, which are fixed on the corresponding foundation and used to support the cylinder for positioning and rotation. The front and rear brackets are composed of brackets, roller frames and rollers. During installation, the height and angle of the equipment can be adjusted by adjusting the distance between the two supporting wheels on the front and rear brackets.

2. Transmission part: The transmission part provides the necessary power for the normal operation of the whole dryer. Its components include a transmission frame, a motor, a triangle belt transmission mechanism, a reducer and a gear transmission mechanism, among which the reducer and the gear are connected by direct connection or coupling to transmit and drive according to the size of the load.

3. Cylinder: The cylinder is the working part of the whole dryer. There are rolling belts for support and ring gears for transmission on the outside, and the lifting plates welded on the inside are distributed in rows. When the dryer is working, the materials are continuously lifted and thrown to form heat exchange to achieve the purpose of drying.

4. Head, tail, air pipe, fire pipe: This part constitutes the hot air circulation and dust removal system required for the dryer to work. The sealing between the head, the tail and the junction of the body is good, so that the hot air can continuously take away the moisture contained in the particles, so as to achieve the purpose of uniform drying of the particles. When the operator needs to enter the inside of the cylinder for work, please enter through the inspection hole when the machine is stopped.

| Model | Motor Power(kw) | Reducer Model | Temp of Inlet(℃) | Angle of Installation(°) | Speed(r/min) | Capacity(t/h) |

| SZHG-0808 | 5.5 | ZQ250 | ≥300 | 3-5 | 6 | 1-2 |

| SZHG-1010 | 7.5 | ZQ350 | ≥300 | 3-5 | 6 | 2-4 |

| SZHG-1212 | 7.5 | ZQ350 | ≥300 | 3-5 | 6 | 3-5 |

| SZHG-1515 | 11 | ZQ400 | ≥300 | 3-5 | 6 | 4-6 |

| SZHG-1616 | 15 | ZQ400 | ≥300 | 3-5 | 6 | 6-8 |

| SZHG-1818 | 22 | ZQ500 | ≥300 | 3-5 | 6 | 7-12 |

| SZHG-2020 | 37 | ZQ500 | ≥300 | 3-5 | 5.8 | 8-15 |

| SZHG-2222 | 37 | ZQ500 | ≥300 | 3-5 | 5.5 | 8-16 |

| SZHG-2424 | 45 | ZQ650 | ≥300 | 3-5 | 5.2 | 14-18 |

Overseas marketing outsourcing services for small and medium-sized enterprises.