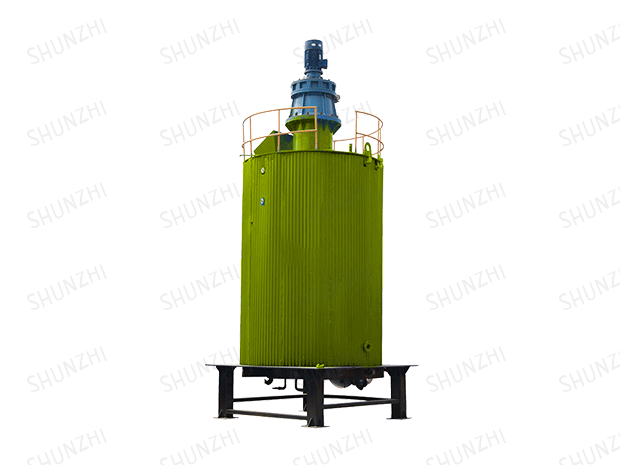

Brand: SHUNZHI

Model: SZFJG-5/SZFJG-10/SZFJG-20/SZFJG-30/SZFJG-90

Applicable materials: Various organic fertilizer production materials

Application scope: Organic fertilizer fermentation

The fermentation tank utilizes the decomposition of microorganisms in nature, and uses the activity of aerobic microorganisms to decompose organic materials through continuous aerobic fermentation in a closed fermentation tank, and generates high temperature by itself to decompose the materials, deodorize and kill the original body. The harmful substances such as parasites and germs reduce the moisture content of the material and the volume, and produce an organic fertilizer rich in a large amount of organic matter.

The fermentation equipment can be used to process organic wastes such as pig manure, chicken manure, cow manure, sheep manure, mushroom residue, traditional Chinese medicine residue, crop straw, etc. Only covers an area of 10-30 square meters), no pollution (closed fermentation), completely kills the eggs of disease and insects (can be adjusted to 80-110 ℃ high temperature), it is a large number of breeding enterprises, circular agriculture, ecological agriculture to realize waste resource utilization Ideal for use. In addition, 5-150m3 different capacity and different forms (horizontal, vertical) fermentation tanks can be customized according to customer needs. During the fermentation process, aeration, temperature control, stirring and deodorization are automatically controlled. When discharging, start the pneumatic discharging device to discharge the material quickly. Full automatic control, no need for workers to operate.

The fermentation tank is a biological fermentation system that feeds from the top and discharges the decomposed materials from the bottom. The sludge is added from the top of the tank and stirred by the internal stirring blades. The stirring blades have a high-pressure fan for forced ventilation and oxygen supply, and the materials in the tank are good. oxygen fermentation. The ventilation system allows the air to pass through the material from the bottom of the fermentation tank, and after being collected in the upper part of the fermentation tank, the exhaust gas is treated by the deodorization system and discharged up to the standard. The effect of high-temperature aerobic bacteria makes the fermentation temperature reach 60-70 degrees, fully kills various pathogenic bacteria, evaporates the moisture in the sludge, and converts organic wastes such as sludge into organic nutrients. A single device can process 5-10 tons of fresh sludge with a moisture content of 60-80%, the fermentation period is about 7 days, and the moisture content of the organic material after fermentation is about 30%.

| Model | Heating power (kw) | Stirring power (kw) | Dimensions (mm) |

| SZFJG-5 | 4×6 | 7.5 | 2200×2200×5300 |

| SZFJG-10 | 4×6 | 11 | 2400×2400×6900 |

| SZFJG-20 | 8×6 | 18.5 | 3700×3700×8500 |

| SZFJG-30 | 58 | 7.5 | 4200×4200×8700 |

| SZFJG-90 | 58 | 7.5 | 5300×5300×9500 |

Overseas marketing outsourcing services for small and medium-sized enterprises.