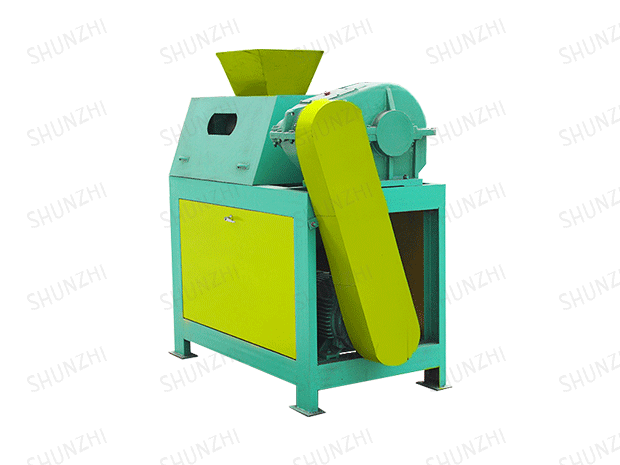

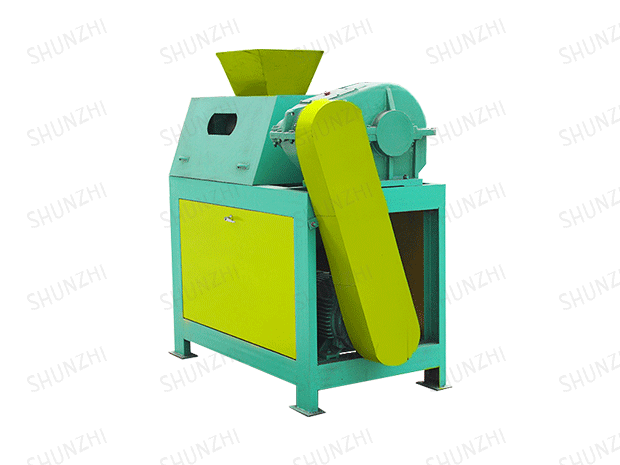

Brand: SHUNZHI

Model: SZJZ-1T/SZJZ-1.5T/SZJZ-2T

Power: 15kw/18.5kw/22kw

Material: urea,ammonium bicarbonate, ammonium chloride,ammonium phosphate, potassium chloride

Application: fertilizer production and processing

The double-roll extrusion granulator is the same as the flat-die extrusion granulator, both of which use the physical dry method to extrude the material. The difference is that the double-roll extrusion is a two-roller rotary extrusion, which can be widely used in the fertilizer processing industry. , feed production units and the chemical industry to granulate, produce and process powder materials.

1. Transmission connection parts include: motor, pulley, V-belt, reducer, chain, sprocket, coupling.

2. The head part: including the bearing frame body, a pair of high-pressure die roll skins, two shafts, etc.

3. Crushing studio: It is composed of crushing roller bearing frame, crushing roller, screen and so on.

1. This machine is produced by no drying process, granulating at room temperature, and forming at one time. It has the characteristics of less investment and good economic benefits.

2. The structure of this machine adopts granulation, forming and screening as a whole, which makes it have the characteristics of beautiful appearance, simple operation and low energy consumption. The main parts such as the roller body are made of a new type of metal with anti-corrosion, wear-resistant and impact-resistant characteristics. The bearing frame body is made of anti-corrosion casting as an integral part, which makes it have the characteristics of good stability, which can greatly improve the service life of the rolling bearing and the large shaft. The transmission part adopts the double input transmission mode, which not only improves the input power ratio, but also ensures the lubrication and sealing performance of the transmission gear. The machine has the advantages of compact structure, good stability, good sealing, low noise, convenient operation and maintenance and so on!

3. Wide adaptability of raw materials, the machine can not only be used for granulation in fertilizer, feed and chemical industries, but also has good applicability especially for rare earth, metallurgy, coal, biological preparations, and environmental protection projects.

The motor drives two relatively moving pressing rollers to squeeze the fertilizer through the gear reducer. The grooves on the surface of the roller squeeze the fertilizer into granules to form granules. Organic fertilizer or compound fertilizer raw material, through the feeding device installed above the parallel rollers, the fertilizer is forced into the roller gap between the two rollers by the friction between the fertilizer and the rollers in the feeding system, and the fertilizer is brought in under the rotation of the rollers. The wavy spherical grooves on the surface press the fertilizer into a sheet with granules, which are broken into small pieces after falling, and then screened to obtain qualified fertilizer granules.

| Model | Power(Kw) | Pellet Diameter(mm) | Roller Size(mm) | Overall Size(mm) |

| SZJZ-1T | 15 | > 4 | 150*220 | 1450*800*1450 |

| SZJZ-1.5T | 18.5 | > 4 | 150* 300 | 1450*850*1500 |

| SZJZ-2T | 22 | > 4 | 185*220 | 1630*850*1650 |

Overseas marketing outsourcing services for small and medium-sized enterprises.