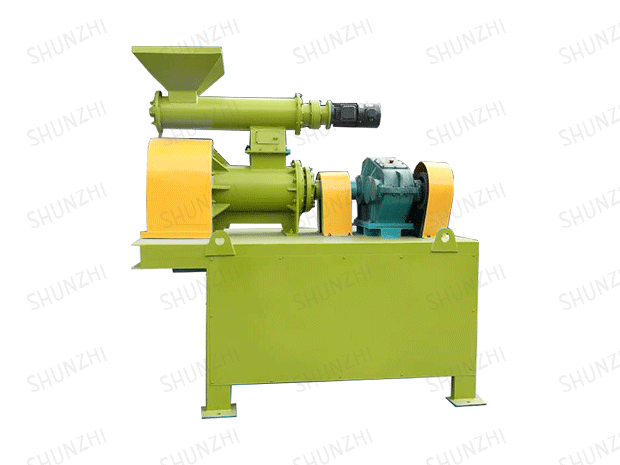

Brand: SHUNZHI

Model: SZSZ-450/SZSZ-650

Power: 30kw/45kw/55KW

Material: Animal waste, plant branches and leaves.

Application: Organic and compound fertilizer processing

The double-die extrusion granulator can directly granulate all kinds of organic materials after fermentation. It does not need to be dried before granulation. The moisture content of the raw materials can be between 20-50. Columnar granules, no need to add binders during granulation, the granules are firm, uniform and beautiful, and the granulation rate is higher while reducing the drying energy consumption. It is widely used in the direct granulation of organic materials such as poultry manure, urban sludge, domestic waste, sugar mill filter mud, paper sludge, distiller's grains, bean dregs, straw, peat and other organic materials to produce pure organic, organic-inorganic and bio-organic fertilizers.

1. This machine is mainly used for (biological) organic fertilizer, compound fertilizer and pellet processing in aquaculture processing industry;

2. The granular materials processed by this machine have smooth surface and moderate hardness. During the processing, the temperature rise is low and the nutrients inside the raw materials can be well maintained; this machine integrates a feeder, a mixer and a granulator into one. ; While feeding the material evenly, it also conducts secondary stirring of the material. The feeder is equipped with a governor, which adjusts the feeding amount according to the dry humidity of the material during production, so that the main machine will not be stuck or useless. The main machine integrates the ring die and the flat die, which is equivalent to the work of 2 granulators.

3. The particle composition is uniform, the shape is neat, and the pore size of the particle thickness can be divided into: Φ5, Φ6, Φ7, Φ8, etc. Users can choose according to production needs when ordering;

4. Due to the low moisture content of the particles, it is easy to store, and can be kept in the original state for a long time in water, which greatly improves the utilization rate of materials.

5. The granulator mold, stirring and conveying blades are all corrosion-resistant stainless steel quenched and tempered; manganese is added to the pressure roll casting and quenched and tempered to achieve anti-corrosion and wear-resistant. Thereby increasing the output and reducing the loss of equipment.

technical parameter

| Model | Capacity(t/h) | Granulation rate | Particle temperature rise(℃) | Power(kw) |

| SZSZ-450 | 0-5 | >95 | <30 | 30+2.2 |

| SZSZ-650 | 0-8 | >95 | <30 | 45(55)+4 |

Overseas marketing outsourcing services for small and medium-sized enterprises.